In recent years, the global community has become increasingly aware of the need to adopt sustainable practices in various aspects of life, including manufacturing and product design. One material that has gained prominence for its environmental advantages and sustainability is acrylic. Acrylic, also known as PMMA (polymethyl methacrylate), is a versatile thermoplastic that offers a range of benefits, making it an eco-friendly choice for a wide array of products. In this article, we will explore the environmental advantages and sustainability of acrylic products.

- Durability and Longevity

One of the key environmental advantages of acrylic products is their durability and longevity. Acrylic is highly resistant to environmental factors such as UV radiation, moisture, and temperature fluctuations. This resilience ensures that acrylic products have a longer lifespan than many alternatives, reducing the need for frequent replacements. Extended product lifecycles contribute to a reduction in resource consumption and waste generation.

- Energy Efficiency in Manufacturing

The production of acrylic materials is relatively energy-efficient compared to other plastics. The manufacturing process involves polymerization of methyl methacrylate, which requires less energy than the production of materials like PVC or ABS. Additionally, acrylic can be molded and shaped at lower temperatures, further reducing energy consumption during fabrication. This energy efficiency helps minimize the carbon footprint associated with acrylic product manufacturing.

- Recyclability

Acrylic is a highly recyclable material. Scraps and waste generated during the manufacturing process can be collected and recycled to create new acrylic products. This closed-loop recycling system reduces the demand for virgin raw materials and decreases the environmental impact associated with acrylic production. Recyclability is a crucial aspect of sustainability as it conserves resources and minimizes waste disposal.

- Lightweight Nature

Acrylic is a lightweight material that can replace heavier materials in various applications, such as automotive components and aircraft windows. By reducing the weight of products, acrylic helps improve fuel efficiency and reduce greenhouse gas emissions. This attribute is particularly valuable in the transportation sector, where every reduction in weight leads to environmental benefits.

- Low Toxicity

Acrylic is non-toxic and does not release harmful chemicals or gases into the environment during its use or disposal. This quality makes acrylic products safe for human health and environmentally friendly. Unlike some other plastics that release toxic fumes when burned, acrylic combustion produces mostly carbon dioxide and water vapor.

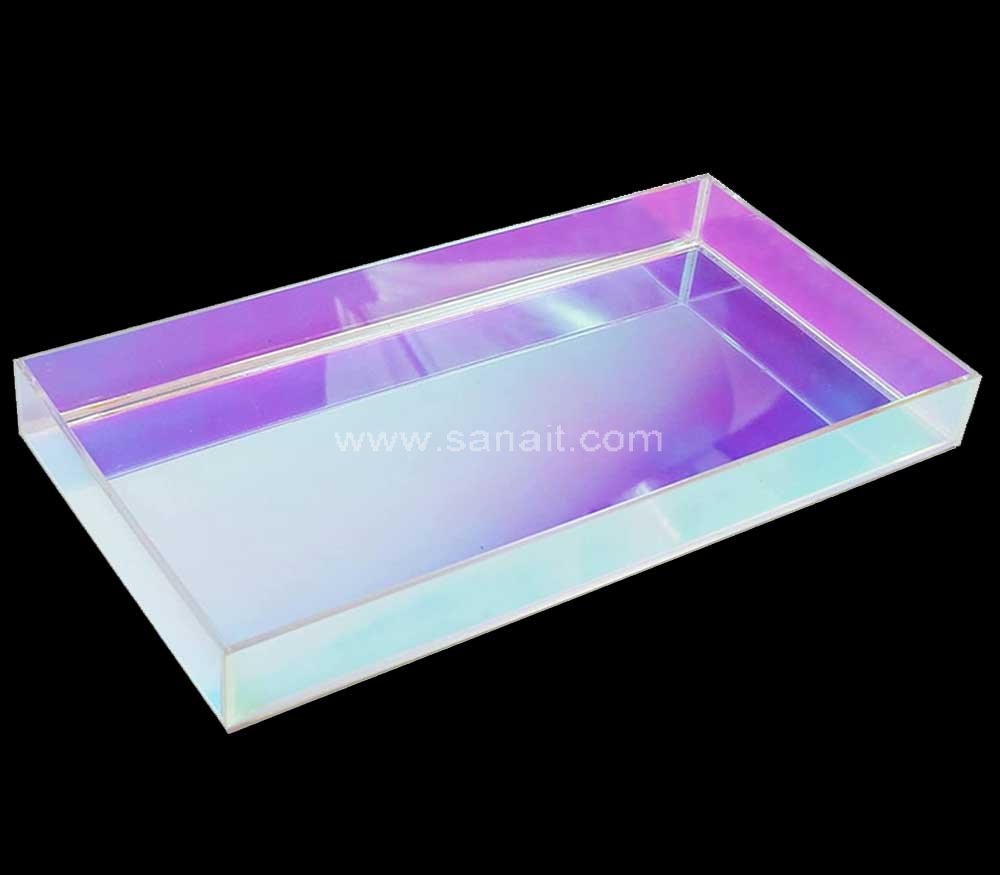

- Versatility and Design Flexibility

Acrylic’s versatility and design flexibility contribute to its sustainability. It can be easily molded into various shapes and sizes, allowing for creative and innovative product designs. This adaptability enables designers to create products that are not only aesthetically pleasing but also functional and efficient, thus reducing waste and optimizing material use.

- Reduced Maintenance

Acrylic products typically require minimal maintenance over their lifespan. They are inherently resistant to fading, yellowing, and degradation, reducing the need for regular replacements and refinishing. Lower maintenance requirements translate to less resource consumption and less environmental impact in the long run.

Conclusion

In an era when environmental sustainability is a paramount concern, acrylic products stand out for their numerous eco-friendly attributes. Their durability, energy efficiency in manufacturing, recyclability, lightweight nature, low toxicity, versatility, and reduced maintenance needs make acrylic an excellent choice for a wide range of applications. By choosing acrylic over less sustainable alternatives, individuals and industries can contribute to a more environmentally responsible and sustainable future. Acrylic’s environmental advantages and long-term sustainability make it a material worth considering in the ongoing quest for greener and more eco-conscious product choices.